LA-600A

High-speed, High-precision Attachment Spindle for Micro-machining

| LA-600A, attached to your existing NC milling machine or machining center, will realize high-speed machining. At a high speed of 60,000min-1(rpm) , this spindle displays superior cutting performance and finishing in small-diameter end-mill cutting or drilling. |

|

|

Maximum revolution speed : 60,000min-1 (rpm)

Spindle accuracy : 1μm or better

High power of max. 370W output and flat torque characteristic

A combination of brushless motor and ceramic bearing

The spindle is driven by a direct-drive brushless motor. Without any speed increase with gears or the like, this spindle causes little heating or vibration, which contributes to producing finely finished surface.

esponsive to various attaching tapers

The spindle can be fitted to various tapers of BT, HSK and other shanks.

Product Specifications

| Revolution speed |

10,000 to 60,000min-1 (rpm) |

| Maximum output |

370w |

| Spindle accuracy |

1μm or better |

| Cooling air supply |

0.2 to 0.5MPa

Clean dry air

4mm tube dia |

Collet chuck

(option) |

Daiya's CCER11-SR used (AA class or above recommended)

Holding diameter : 0.5 to 6.0 mm (Chuck nut wrench included) |

●BT50-type Diameter

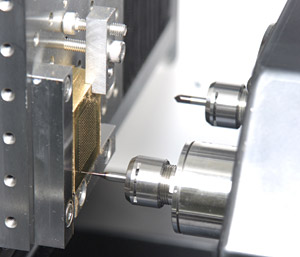

Installation photograph of machining

Data on grooving in hardened die steel

| Comparison of machining data between the conventional general-purpose machining center and the LA-600A attached to a general-purpose machining center. |

| Material |

SKD11 (HRc61) |

| Tool |

Carbide solid molded end mill (non-coated) |

| Groove length |

143mm |

| |

LA-600 |

General-purpose machining center |

Revolution speed

N [min-1] |

50,000 |

5,000 |

Feed rate

F [mm/min] |

250 |

15 |

| Depth of cut (Z direction) [mm/min] |

0.1 |

0.05 |

| Relative roughness of surface |

○(Visual) |

○(Visual) |

| Tool life |

○ |

x |

| Grooving time [min] |

3min 40sec |

40min or more |

|

|