1.Quick change rubber-steel segment collet

2.Ideal for bar and shaft clamping

3.Round, square and hexagonal collects available

Category (227)

1.Interchangeable top jaws grip the workpiece O.D.

2.Workpiece is pulled down to location for high accuracy machining

3.Air sensing available

4.Air/ Coolant through the spindle available

1.Pulled down to location for accuracy

2.Collet changes quickly for machining a variety of workpieces

3.Air sensing can be added for automatic loading

1.Ideal for clamping thin-wall and fragile workpieces without distortion

2.Floating clamping fingers adjust to workpiece shape

3.Available in 2-jaw, 3-jaw , 4-jaw models

1.Accuracy to 0.002mm ideal for hard turning gears

2.Counter centrifugal design

3.Sealed body eliminates maintenance

4.Jaws changes easily for quick set-up

5.Self-contained cylinder

1.Diaphragm chuck for hard turning/ grinding gears

2.Fast jaw and clamping cage change for easy setup

1.Finger chuck for high accuracy clamping of bevel gears

2.Floating action ensures equal clamping force on all 3 fingers

3.Available with hydraulic and pneumatic actuation

1.Ideal for clamping workpieces with small gripping surfaces

2.Sliding jaws clamp the component; then, the enhire chuck body pulls down to location for accurate machining

1.Ideal for clamping workpieces with small gripping surfaces

2.Sliding jaws clamp the component; then, the enhire chuck body pulls down to location for accurate machining

1.Machine multiple surfaces in a single clamping

2.On-the-fly indexing

3.Accurate, durable indexing system

4.Index positions 4 x 90˚ or 8 x 45˚

1.Machine multiple surfaces in a single clamping

2.On-the-fly indexing

3.Accurate, durable indexing system

4.Index positions 3 x 120˚ or 6 x 60˚

5.Accurate, durable indexing system

1.Machine multiple surfaces in a single clamping

2.On-the-fly indexing

3.Accurate, durable indexing system

4.Index positions 3 x 120˚ or 4 x 90˚

1.Machines shafts in one single clamping operation

2.Change jaws and face driver to machine different sizes of shafts

1.Jaws float on spherical bearing to determined clamping points

2.Spring or fixed center available

3.All three jaws apply constant gripping force

1.Ideal for machining aluminum wheels

2.Accommodates a variety of wheels by changing jaws and arms

3.Lower weight increases efficiency and reduces down time

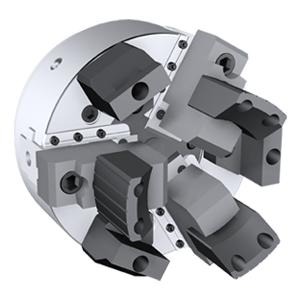

1.Reduced set up time; all 3 jaws changed in less than one minute

2.Built-in safety mechanism prevents jaw movement to ensure proper jaw engagement

3.High alloy steel material and heat treatment increase robustness

4.Reboring of machine jaws unnecessary (tolerance within 0.02mm)

5.High T.I.R. and repeatability

1.Ideal for gripping large diameter pipe

2.Built-in non-return valves maintain the air pressure during machining

3.Self-contained actuation eliminates the need for hydraulics

1.Self-Contained Cylinder Chuck for Compact installation Area

2.Compatible with NC Rotary Table

3.Built-in Lock Valve

1.Compact design with built-in cylinder allows for larger machining area

2.Suitable for long workpieces

3.Compatible with air blow

1.Compact design with built-in cylinder enables wider workspace

2.Compatible with hydraulic Chucks